I’ve recently began making things on a CNC machine. Anyone can buy a CNC but the learning curve can be steep especially as it relates to bits. There is SO MUCH to know. What bit do you use for what type of cutting action, what speed, what feed? What the same bit in different materials will do. Screw up your cuts and you will snap a bit in a heartbeat. Or you can dull a bit. Even the right bit with the wrong settings can burn or tear at your substrate.

To further exacerbate the situation ……….. BITS ARE EXPENSIVE. Snap a $40 bit and it hurts more than your pride. Also, because of the high cost of bits, at least initially, you’ll probably only have one of each type of bit. Snap that bit and you’ll have to wait a few days to get a new one.

I started this journey with a Sainsmart 3018 Prover machine.

Cutting with 1/8th bit

In this pic I used a 1/8th end mill to cut out my name in a semi-3D relief manner.

Took quite a while to make this small design. To speed things up, many CNC operations require the use of multiple bits during a single design creation.

Cut, change bit, cut, change bit, etc.

I probably could have cut this out much quicker by using a larger bit to clear the big empty spaces and then coming in and cleaning up around the name.

That sure is easy for me to think about now but when I made that John sign I didn’t HAVE ANY BIGGER BITS. My machine only came with engraving bits and then I went on line and bought a little bit set that really wasn’t money well spent.

Heck, I didn’t know.

So then I went to Harbor Freight and bought a router bit set that had 1/4″ shanks. I bought a 1/4″ collet and THE BITS DIDN’T FIT. Seems the Chinese bits were 7mm in diameter which is 0.275″.

Heck, I didn’t know.

Ultimately, the point I am trying to make is that my first few bit purchases were stupid and not backed up by any hard skills or knowledge or experience.

I learned a few things, and then I bought a Next Wave Shark HD500 CNC machine. This machine uses a proper router that accommodates 1/4″ bits. But know this about bits……..the thicker the shank……….THE MORE THEY COST. The little 1/8th inch bit sets I bought for my smaller CNC were pretty cheap.

The 1/4″ bit sets………..Not so much. After reading lots of forum posts and watching lots of videos on YouTube I decided to invest in some decent bits. The first set I bought was an Amana Tool AMS 177 – K bit set at $208. OUCH! These are bits that you really don’t want to snap.

Amana Tool Bit Set

And while it is a really, really nice bit set I feel like it is missing a tool or two.

I would have loved to see a 1/8th ball nose bit in this set. And maybe another 1/16th inch bit.

At any rate, that is just my opinion. And you can of course buy bits separately if you know what you want. But when you are first getting started……..you don’t know what you want.

I did buy a 1/8th inch ball nose and then a 1 1/8th inch Surfacing bit. So at the moment I feel like I have a decent mix of bits that do what my skill level supports.

One great thing about these Amana Tool bits is that they come with a database for Vectric Software. This is worth the price of admission right here. The tools have preset cutting parameters. And while you will want to tweak settings……….you’re off to a great start, especially if you haven’t quite gotten a great grip on speeds, feeds, and stepover settings.

But if you are a new guy, like me, reading this…………here is my recommendation to you regarding the purchasing of bits.

Start with this bit set from SpeTool.

SpeTools Starter Set

This set is SIMILAR to the Amana Tool set however it is less than half the price at $87. You can get 15% off as well if you sign up for their newsletter.

And once again, the elusive 1/8th ball nose evades me. No biggie.

SpeTool also has an importable database library for Vectric Software and it is really new. In fact I haven’t had this set very long at all and the database came out after I purchased mine.

I can’t and won’t do a comparison on which set is the best quality. I simply don’t have enough time on either set to make that call. I will say that early on in my journey I cut a lot of pine, oak, and cherry. I have had excellent results with the SpeTool and Amana Tool bits. Both seem to work exceptionally for MY NEEDS. The Amana bits are coated with ceramic and claim to maintain superior sharpness. I don’t doubt this but I don’t have long term experience yet. One would hope that double the price nets you double the longevity.

With that being said you can buy 2 sets of SpeTools for the price of 1 Amana set. My CNC runs at best an hour or two a day, and not every day. I typically do one project a day. I do not even remotely have a production environment which would wear down my bits provided I use decent settings while cutting.

After you buy a beginners bit set and you make 10 or 20 projects you’ll quickly learn what your “Go To” bits are. My next bit purchase will be multiples of certain bits (like the 1/8th inch ball nose) that I use routinely.

Also I’ll add this statement before I wrap it up. If you make big pockets or trays that clear out a LOT of material……….by all means………..get some really cheap bits. I use a 1/2″ cup bit for making trays and it works great. Save money on bits when you can. You can buy a lot of those cheap bits for that tiny price and use them until they wear out. Chances are they won’t wear out for years if you use them right.

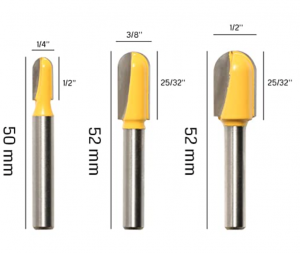

Genmitsu Round Nose bits

WRAP UP STATEMENT:

Buy the SpeTool starter set if you are just getting started. They are high quality bits, with a database library at an excellent price.

Don’t buy a bunch of cheap bits like I did. I didn’t even understand what the first few bits I bought were for.