I have been having serious fun with my Next Wave Shark HD500 CNC since I got it. Prior to Thanksgiving I had essentially done no woodworking in my life and in just 6 weeks or so I’m really getting the hang of it and making some decent creations.

And I keep learning stuff. And I like to keep notes when I learn stuff so I can save that information for posterity because I have a terrible memory. Here’s the latest batch of stuff I have learned.

It’s all about the setup with CNC. Vectric Vcarve software is outstanding in how it can simulate the Toolpaths you generate and show the cuts.

Provided you set up your project with the right size and thickness the simulation is darn near spot on. Once you get your Toolpath generated then it is a matter of transferring it over to the machine.

This is where you channel your inner German old man machinist persona. Think about where the the wood lies on the CNC bed. What direction to set it in. How to clamp it. The simulation will show you on your properly sized workpiece where the bit will run to. Set your clamps up accordingly. Secure the piece, then test it to see if it moves. Check it again, and then do it again.

Then set your machine X and Y axis and then finally zero the Z axis. Once you are CONVINCED the design is good, the clamping is good and the machine is set up correctly, then and only then, do you hit start on the job and then by golly you stay there until it is done. Routers spinning at 13,000 rpm or higher with loose pieces are DANGEROUS so you want to stay there SAFELY. Don’t hover over something that can be a projectile.

I know I haven’t laid down earth shattering advice here but seriously……..you just have to have the patience of an old, very well trained machinist before you start throwing wood chips.

Some other things I have learned:

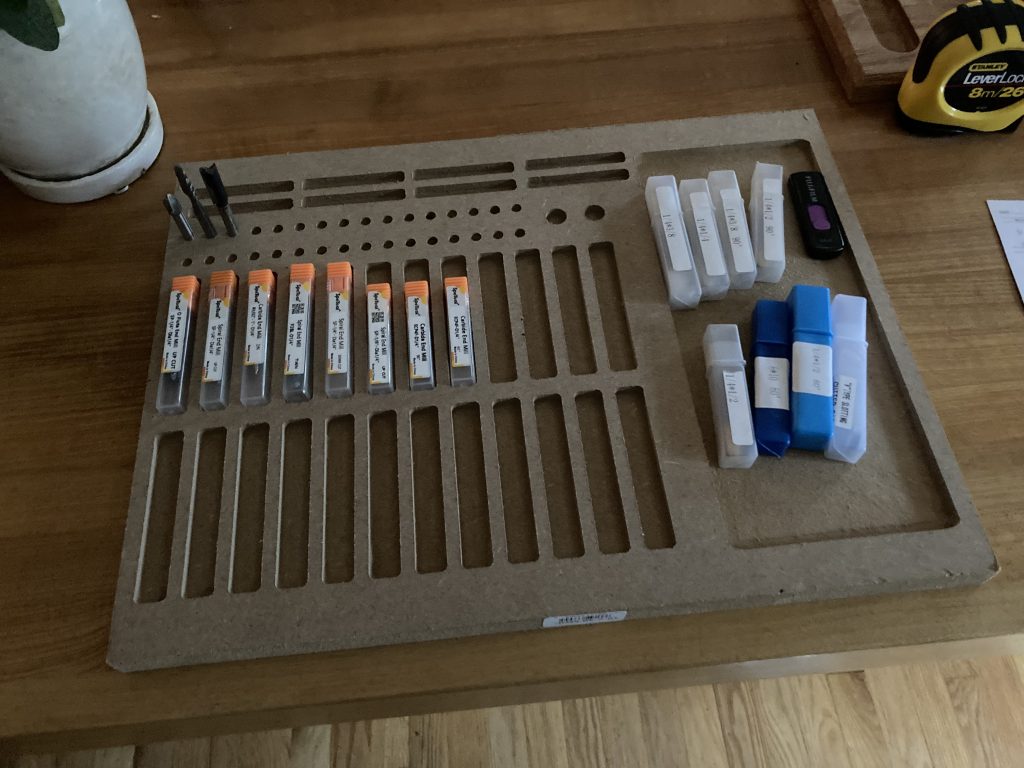

- Starter bit sets aren’t really all inclusive. I bought a couple kits only to buy some loose bits.

At a minimum to do beginners work you want some end mills, up and down cut, both 1/4 and 1/8th inch, some ball nose bits, maybe 1/16th and 1/8th, some V bits for engraving both 60 degree and 90 degree, and maybe a cup bit for getting some rounded pockets.

Yes, you will need and you will want MORE, but in my humble few weeks of experience that will keep you busy for a while.

And because most of these bits and sets cost a few bucks you’ll want to pay particular attention to your speeds, feeds and plunge depths so you don’t snap off a bunch of expensive bits.

Also places like Amana and SpeTools have bit libraries that you can download into your Vectric Software. It makes choosing the EXACT BIT a breeze which makes your simulation and finished project even that much more accurate.

2. Having said that maybe start off with SOFT woods to practice on. Plunging 8mm deep in one pass accidentally is two different events on Baltic Birch compared to some super hard Maple.

3. Even though you have a CNC with awesome detail bits you still have to sand and post process your project. Get some rotary sanding disks and lots of sandpaper.

4. Wood at the big box stores is EXPENSIVE. Wasting wood, which is going to happen is going to have an economic impact. Not everyone will be able to do this but with some simple tools like a saw and a planer you can source wood locally. Check this out. I found a guy selling FOURTEEN approximately 4′ long x 1.5″ thick, live edge cherry boards for $100. One single board should cost that much. Since I have the aforementioned saw and planer I was able to run it through the planer until it was a stunning piece of wood ready for making cool stuff.

Making Toothpicks (click pics to enlarge)

I challenge you to walk into Lowes with $100 and see how much good quality hardwood you can walk out with. Not much. You may not ever find a deal like I did but buying wood locally or even re-purposing wood from old furniture or barns or whatever will save you big $$$$. Keep your eyes open for local sources. And while this may seem odd you may even find a hunk of wood laying on the side of the road that is nice and weathered. Old boats sometimes have teak on them………..you get the picture. There is wood all around that can be re-used and wood quite literally grows on trees. 😃

Remember, I haven’t been doing this long. Here are my last few projects. And I will say it again……I never wood worked before Thanksgiving of 2021. Everything below I would classify as beginner projects. Nothing is really complicated at all. Some required some bit changes mid cut but nothing too tricky. Imagine what you could do in a year or two of steady learning?

Some recent projects (click pics to enlarge)

This has been a fun, and learning experience and hopefully soon I can sell some of this stuff.